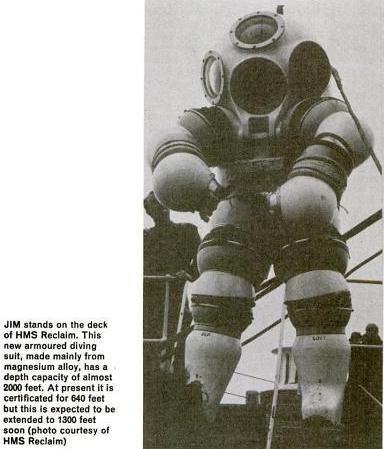

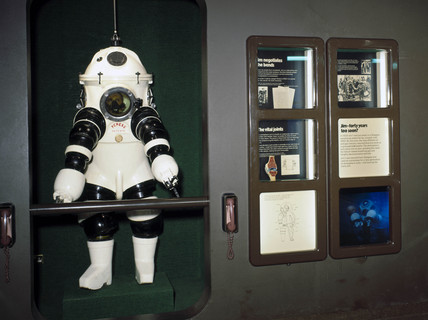

1969 – JIM Atmospheric Diving Suit by Mike Humphrey, Mike Borrow, Richard Tuson and Joseph Salim Peress.

The original Peress Tritonia suit is in the middle, surrounded by type 2's with type 3 arms, then standard type 2 JIM suits on the outer. Image from www.DiveScrap.com.

The Canadian Diving Symposium

31 October – 1 November 1977

Technical Report – D.J. Fullerton

THE ATMOSPHERIC DIVING SYSTEM; "JIM"

By Mr. Phil Nuytten

Can-Dive Oceaneering

North Vancouver, B.C.

Note: No images appeared in the original article.

Enter "JIM"

Personalising the ADS by giving it the name "JIM" was done somewhat tongue-in-cheek by DHB Construction Ltd., although it was meant as a genuine tribute to "Pop Peress's" first test diver, Jim Jarrett.

A problem, more physiological than technical, is the fact that the suit gets all the credit rather than the operator. The press seldom say, "John Doe, wearing an ADS, set a new depth record", but "Jim sets new record"–very demoralising for the operator!

Another problem that arose is a familiar one in the aeronautics or aerospace industry. From "JIM's" progeny sprang names "JIM 2", "SAM 1", "SAM 2", "WASP 1" and with it the difficulty of determining precisely what model is being discussed.

ADS Terminology

Basically, the ADS is discussed in-house, using the following terminology:

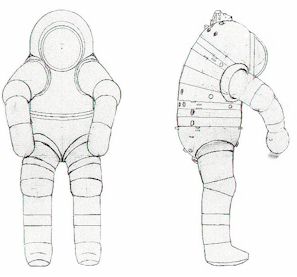

a. Type 1 (JIM) – The original prototype "JIM" utilizing a cast magnesium alloy body.

b. Type 2 (JIM) – A modified version of the Type 1, but using the same material for the body casting.

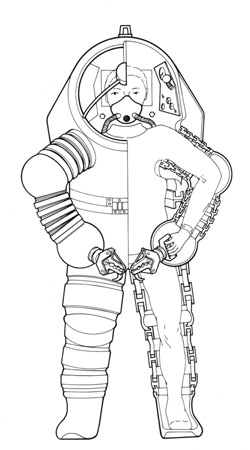

c. Type 3 (SAM) – Sam is a smaller, more compact version of JIM and uses a fabricated aluminum body and a re-configured joint system.

d. Type 4 (SAM) – SAM 4 is a redesign of SAM 3 using a fibreglass body shell.

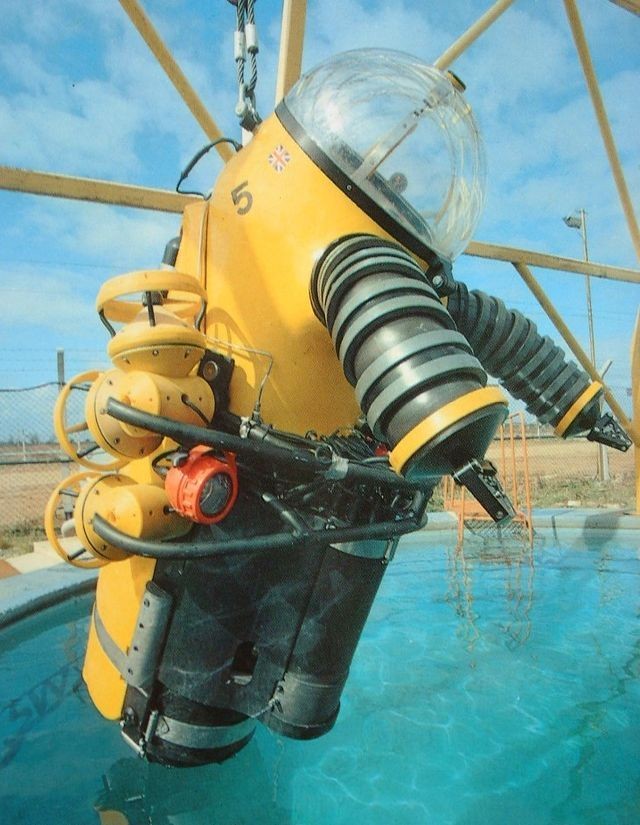

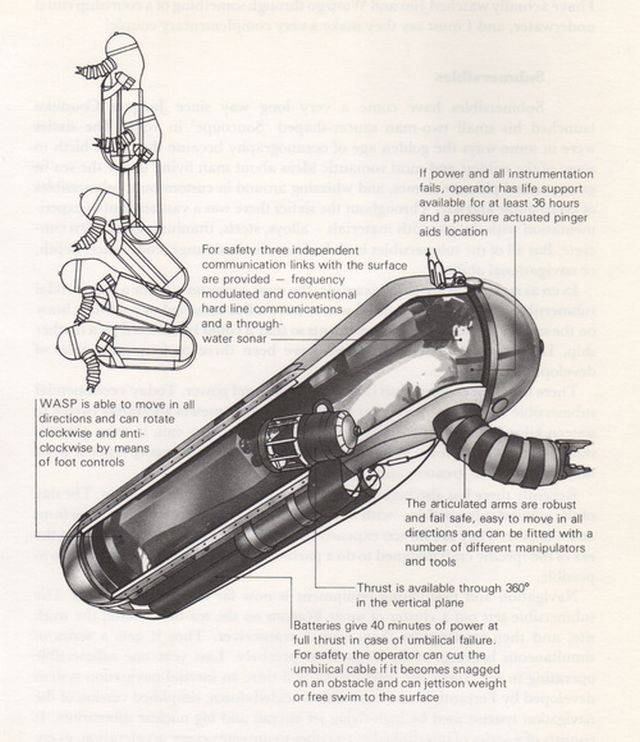

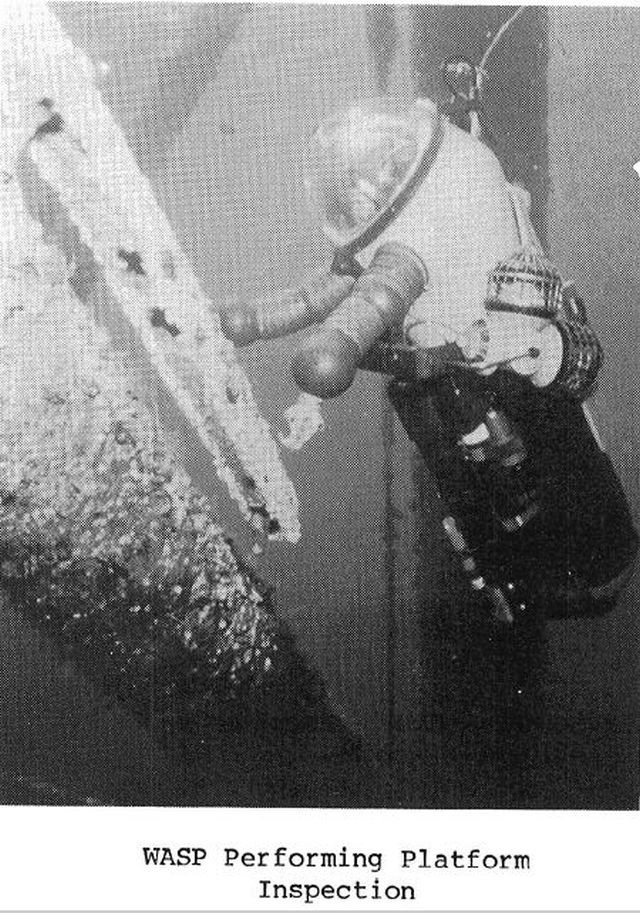

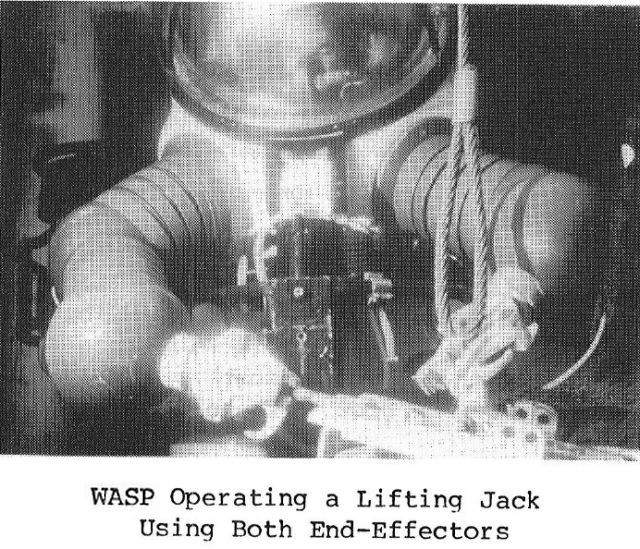

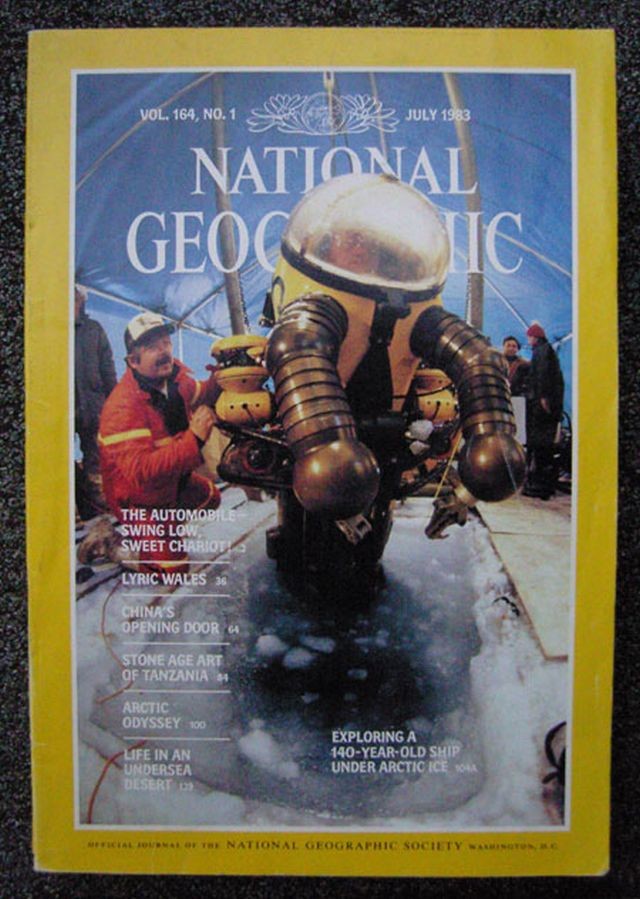

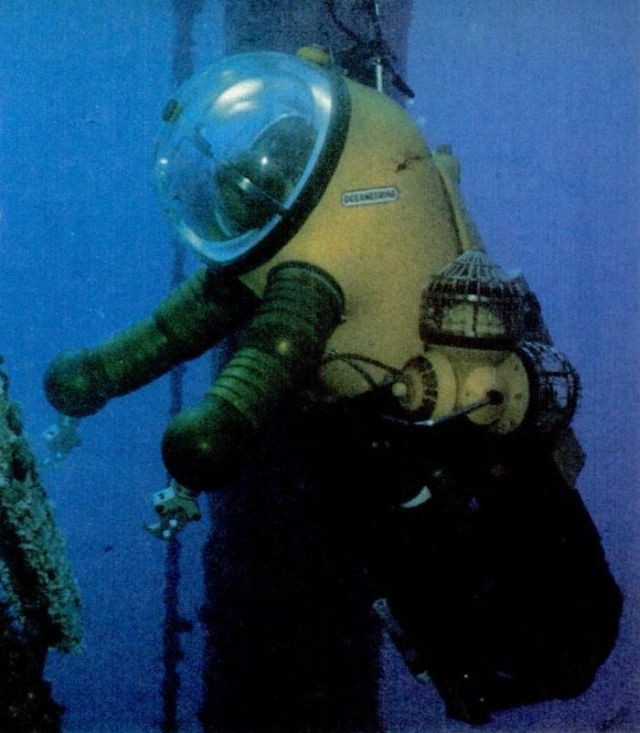

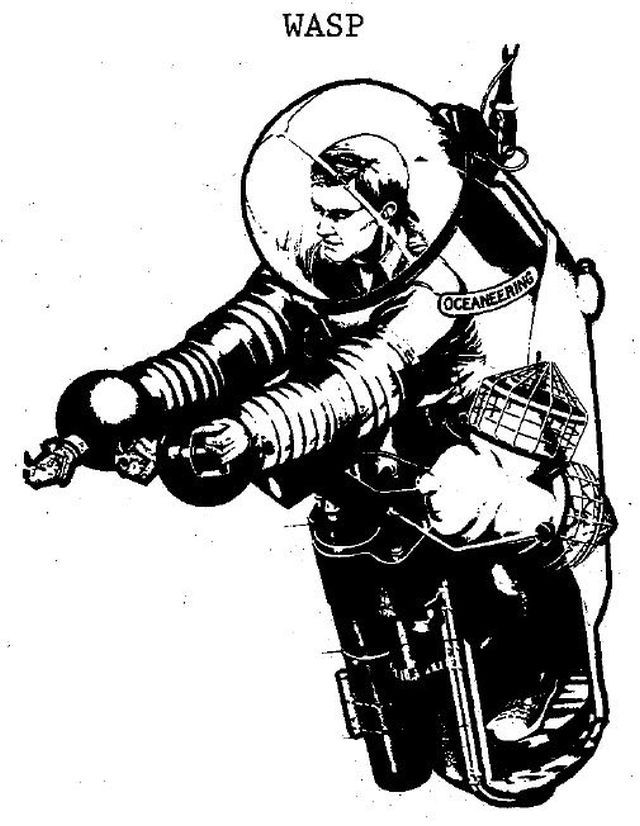

e. WASP – A mid-water unit using thrusters and a tubular lower body section rather than articulated legs.

Type Description

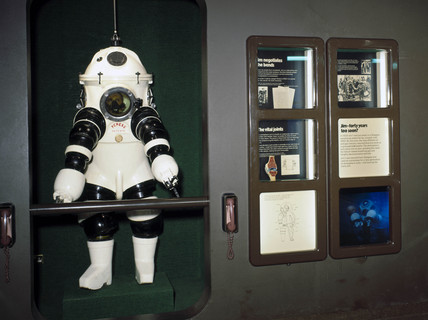

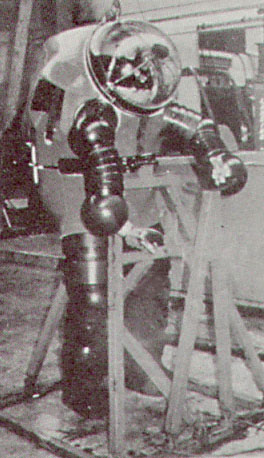

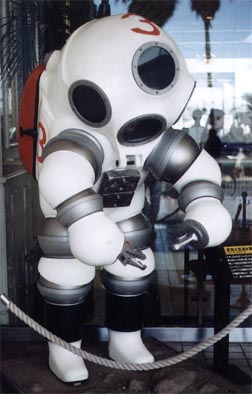

Original restored Peress "Tritonia" suit, now designated as "JIM Type 1" at the London Science Museum. See also separate post on Peress Tritonia suit from the 1930's.

Type 1 (JIM) – The original "JIM" prototype is not used operationally but serves as a design-change and accessory test platform in the Alton Plant.

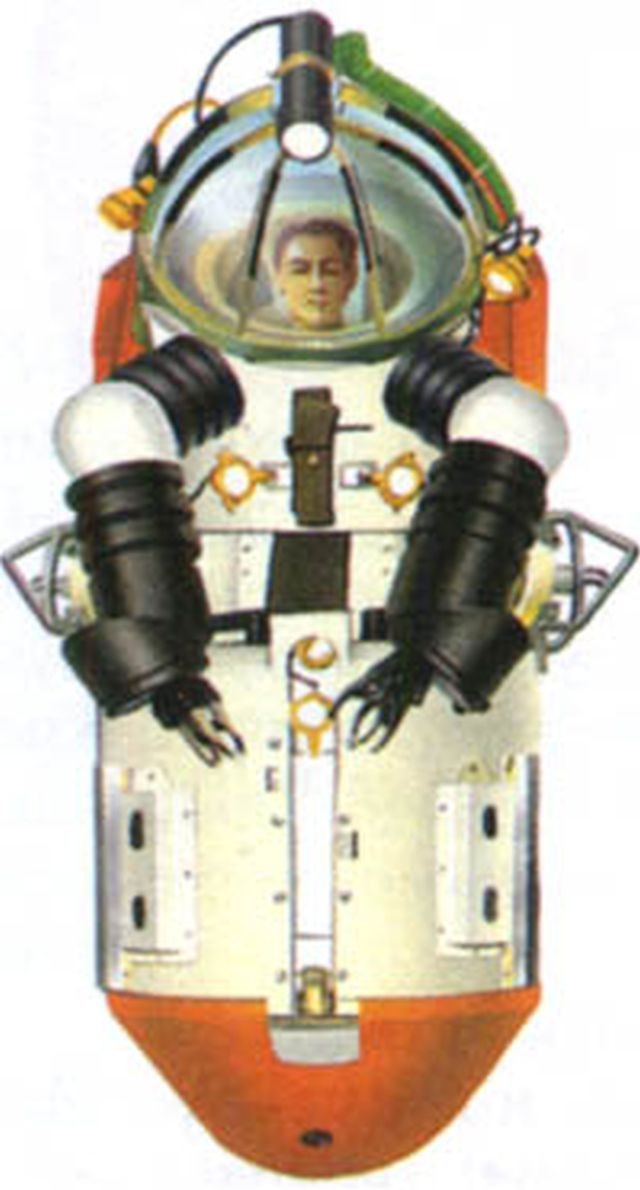

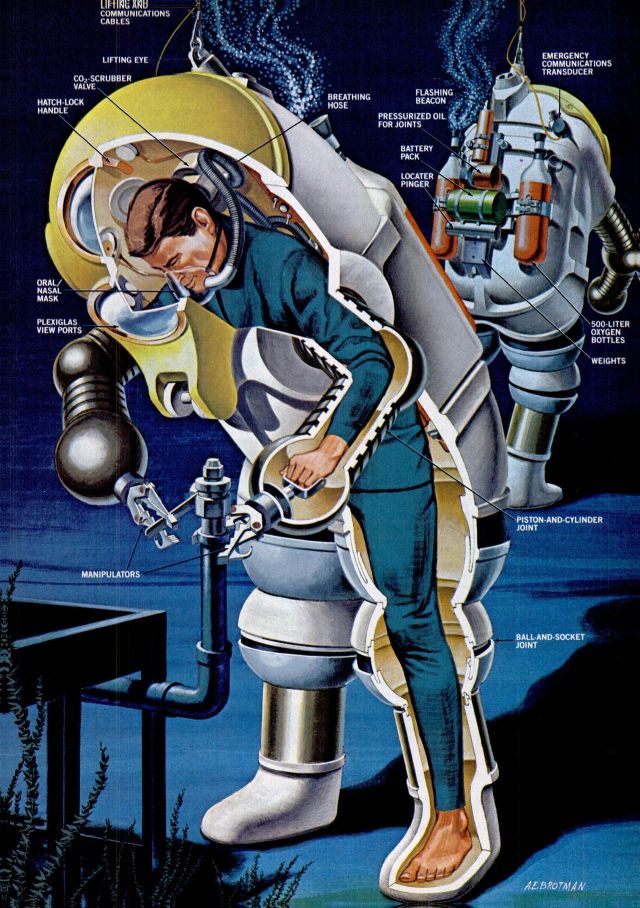

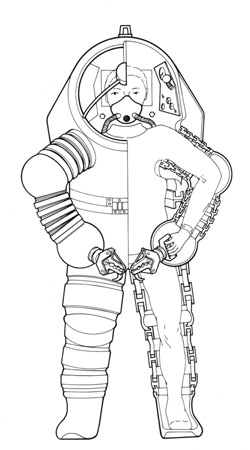

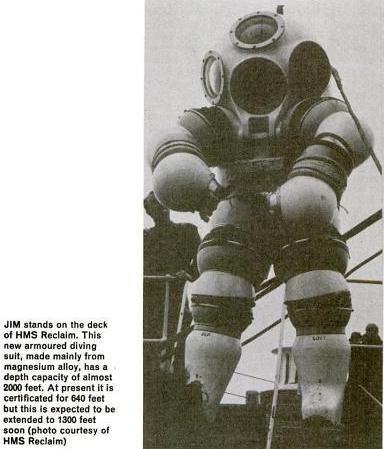

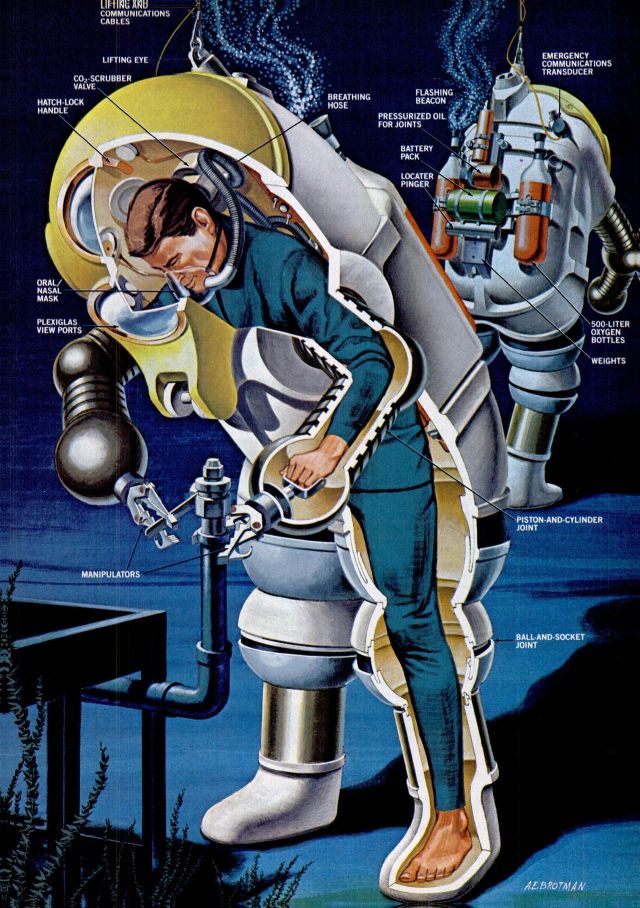

Type 2 (JIM) – The type 2 is the configuration most familiar to the public because of extensive press and trade journal coverage. The type 2 has a body section of cast magnesium alloy with operator entry through a hinged head dome. The limbs utilize a patented semi-sphere joint system originally designed by "Pop" Peress so further modified by UMEL designer, Mike Humphries. The joints use a fluid bearing and allow flexion extension as well as rotation. The elbow and hand pods, the boots and the leg spacers are made of both magnesium alloy and glass reinforced plastic. Vision is through four optically-ground ports in the head dome section.

[cyberneticzoo: There appears to be a hybrid version of a type 2 body with type 3 arms – see pics below.]

Source: Popular Science, May 1983.

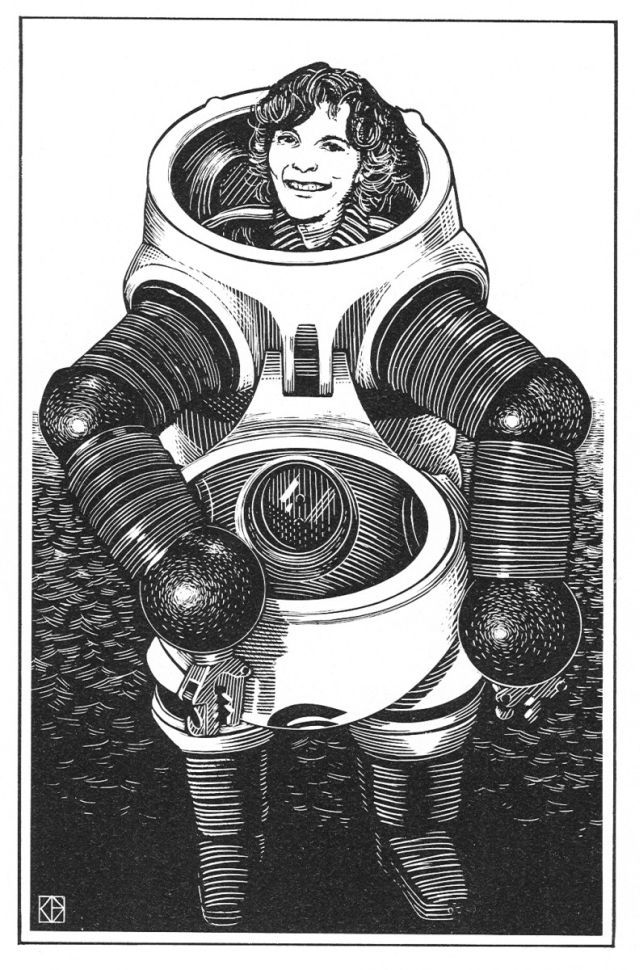

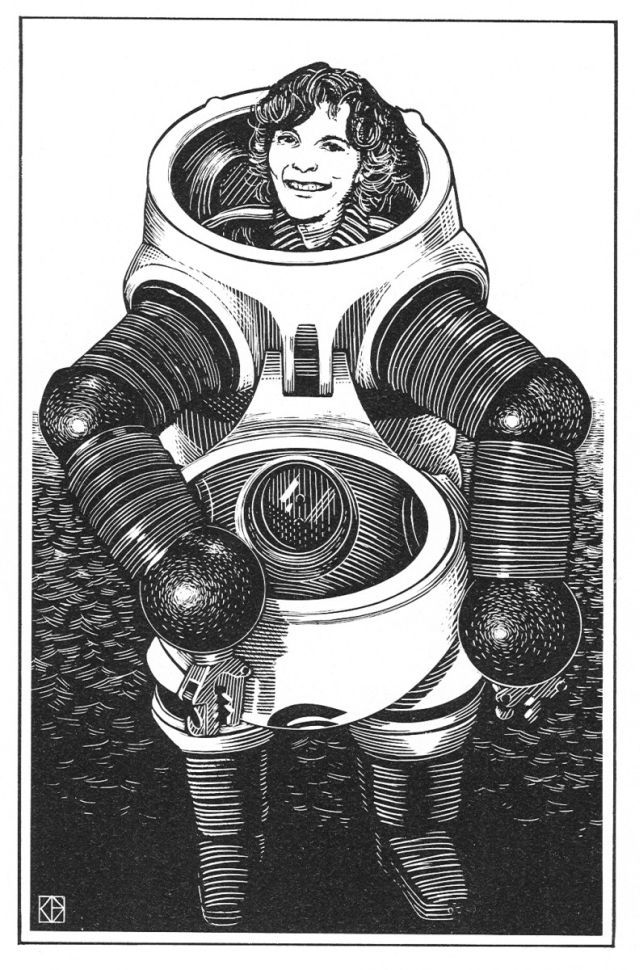

Sylvia Earle – Source: The New Yorker, 3 Jul 1989.

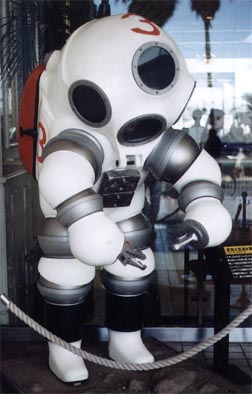

Type 3 (SAM) – The type 3 SAM is a somewhat smaller version of JIM and has its operator entry through a hinged mid section. The body is fabricated of aluminum rather than magnesium alloy which results in a reduction of depth rating but allows a such shorter building time and a drastically decreased post-dive schedule. A major change from JIM is the limb system. The type 3 limb uses a joint design, perfected by Mike Humphries that allows a significant increase in the articulation range with a decrease in physical size. Although the type 3 joint is essentially a modification of the currently patented type 2 joint, it is different enough to be the subject of an additional series of pending patents.

The operator's viewing system is also altered and a single semispherical port replaces the four port system in the type 2 JIM. The hand manipulators have been re-designed from the original parallel-jaw grip to an opposed digit manipulator that allows angular deflection as well as rotation, relative to the hand pod. It should be noted that all the manipulators have been designed to fit any ADS in the series so that no particular manipulator is standard to a suit type, but rather can be fitted for either general use or specific task functions. These changes on the type 3 SAM ADS result in a more compact unit that closely follows the lines of the human body. Wearing the type 3, the operator feels more "man-in-sea" than in the JIM unit and the increased mobility heightens the effect.

Some images sourced here.

Some images sourced here.

Type 4 (SAM) – SAM 4 is essentially the same as the type 3, but has a body shell fabricated from a high density re-inforced plastic material. The result of this change will be to increase the rated working depth to a level even greater than the original JIM systems as well as virtually eliminate the troublesome post dive maintenance. Because of the materials used in the JIM series, corrosion has always been a serious potential problem. Avoidance of this problem has entailed rigid specifications on coating materials and applications as well as a routine post dive inspection of virtually every square inch of the suit surface. The non-metallic type 4 will not require the same rigorous post dive procedure. [ cyberneticzoo:This suit, I believe, is also referred to as a JAM suit.]

WASP – See here.

DHB Construction Limited was formed in 1969 by Dr David Dennison, David BL Hibbert and Mike Borrow and was based in Alton, Hampshire. DHB was formed to enable Underwater and Marine Equipment Limited (UMEL) to receive the finance it required to develop an atmospheric diving suit or ADS (also referred to as an articulated or armoured diving suit). Atmospheric diving suits are made of rigid material which protect the diver from high external pressures, allowing divers to work at greater depths – up to 2500 feet or 758 metres – without undergoing decompression treatments. The articulated joints on the suits allow divers to complete a range of tasks underwater, many of which could not be completed by remotely operated vehicles (ROVs).

UMEL and DHB's ADS design was based on a suit developed by Joseph Salim Peress (1896-1978) in the 1920s. Peress' armoured 'Tritonia' diving suit used a patented hydraulic joint and was used to locate the SS Lusitania off the Irish Coast in 1935. Although Peress' suit was tested by the Royal Navy, there was little interest in the use of the suit by the Navy or commercially at the time. By the late 1960s the expansion of the offshore oil and gas industry had created a potential market for atmospheric diving suits, and UMEL and DHB received a grant from the British Government through the National Research Development Corporation (NRDC) to support the design and construction of their ADS. The majority of the initial design work was carried out by Mike Humphrey, Mike Borrow, Richard Tuson and Salim Peress. The suits were named after the diver on the Lusitania dive, Jim Jarrett, and Peress's original suit became known as the ADS Type I or JIM 1.

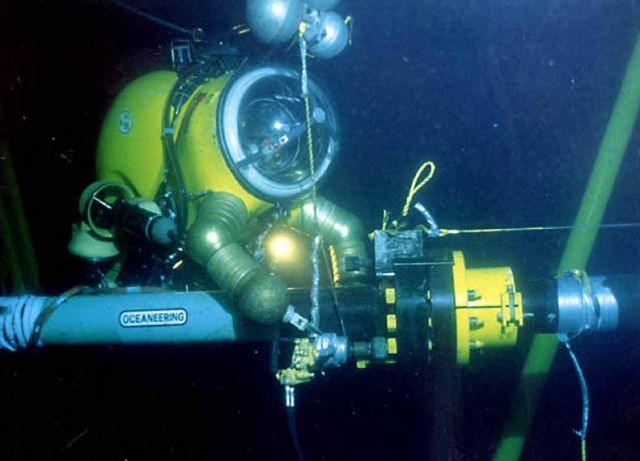

JIM 2, completed in November 1971, was tested in the diving tank of the Royal Navy's experimental diving unit at Portsmouth, HMS Vernon and the pressure chamber at the Admiralty Underwater Weapons Establishment (AUWE) before undergoing sea trials from HMS Reclaim, the Navy's salvage vessel, on the West Coast of Scotland. Test dives of 1000 feet were achieved at AUWE and the suit reached 400 feet in the Reclaim test, and was only prevented from reaching deeper depths by the limitations of the Reclaim' support divers. Additional trials were completed with BP, the AUWE and the Royal Navy Physiological Laboratory between 1972 and 1974. A second model, JIM 3, was constructed and tested in 1972, and later models were constructed in fibreglass (the JAM suit) and aluminium or reinforced plastic (the SAM suit). The JIM suit was first used commercially in 1974, carrying out work for Retrasub in the Canary Islands and an attempted well head recovery for Occidental in the North Sea. Oceaneering acquired the rights to licence the suits in 1975, which led to an increase in their use for deep sea diving in the oil industry. By 1981 there were over 19 suits in existence.

Source: here.

JIM suit Experience:

In the late 1960s—with North Sea diving booming—two Britons, Mike Humphrey and Mike Borrow, formed Underwater Marine Equipment. They'd decided to build their own atmospheric diving suit. Through their research, they found their way right back to Joseph Peress and the Tritonia suit [from the 1930’s], tracking it down in Glasgow and refurbishing it. Legend has it that the Peress himself, who was born in the 19th century, tested the restored suit.

In 1971, the inventors finished their own version, the JIM suit, named after Jim Jarrett [sic]. They formed a company called DHB Construction to commercialize their invention. And they hired a very young engineer named Graham Hawkes.

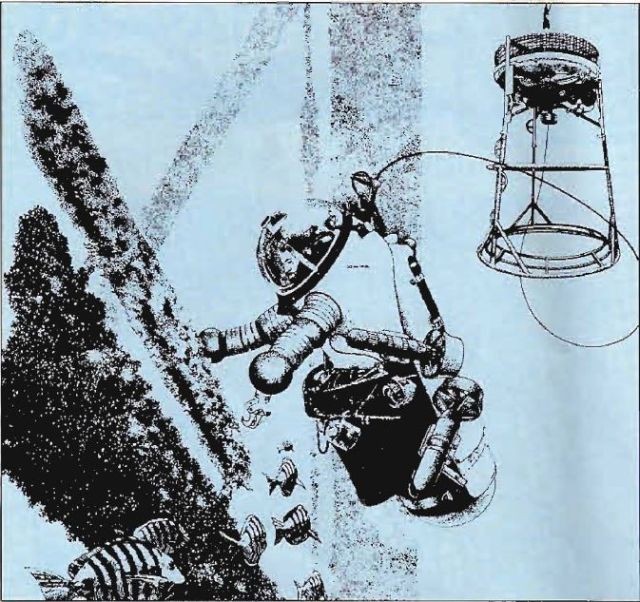

"One of the things that's very different from scuba is that you're breathing normally and there are no bubbles. You are very aware of your breath. This is gonna sound a little strange, but: You can't see water. There is no splashing. There's no nothing. It just felt like I was standing on an alien planet. I felt like I was on the surface of the moon. The water was so clear, it looked like a hazy atmosphere," Hawkes told me about standing on the bottom of the Atlantic Ocean in a JIM suit.

"There were small creatures burrowing. What we know as sediment was drifting away—it looked exactly like smoke. I was just wrestling with all of these images which nothing can prepare you for," he said. "I was an adult at that point but there is no precedent for it. Everything looks alien and all you want to do is let your jaw hang slack and just stare and try to absorb stuff."

"It was the first time I'd ever dived in the ocean. I'd never scuba dived. I'd never even really snorkeled. I'd been in all kinds of Navy tanks testing these things, but never in the ocean," Hawkes said. "It was a commercial operation with a JIM to try and salvage some things, which were in the Atlantic. And I ended up jumping in the JIM suit and standing on the seafloor at 300 feet. I was supposed to be walking around looking for supertanker anchors, big massive chains. There was supposed to be one near me."

"But what happened was, I was stunned by the sea life. I must have been this great big alien that just landed there, but nobody cared. If you go into a forest, all the animals kind of flee. Here they were all just carrying on, and there are things crawling around on the sea bed and fish and things flapping past me. And they were not fleeing. I ended up turning around and around and around just staring at the sea life. I was just in awe. In turning round and round, I ended up digging a hole. I dug such a hole that by the time I came out of my reverie, I asked the top side to lift me up and they just dragged me all the way out of there," Hawkes concluded.

Hawkes is not describing the moment in the photograph that inspired this story. He is, instead, talking about his first experience with a JIM suit in the ocean.

He spent a lot of time in these suits in those early years. While the JIM suit had its advantages over saturation diving, the user experience was not pleasant.

The JIM suit's leg mobility max, from a US Navy report.

As one descended, the viewports were designed to slide in a bit, but they didn't slide in smoothly. They'd pop into place and Hawkes says it was like having a rifle go off in your face … as you're descending hundreds of feet into the abyss. Saltwater and oil from the joints would pool around one's feet. And as he moved the limbs of the suit, they tended to "grab a piece of flesh and bite you," Hawkes put it.

The mobility of the suits was limited and required a lot of strength. The legs, such as they were, could not bend at the knee, so the people testing them had to swing their legs out to do any kind of locomotion. Imagine walking on stilts. It took the some getting used to.

Lieutenant Robert C. Carter of the US Navy evaluated the JIM suits in 1976. Their maximum walking speed was about 50 feet per minute, a small fraction of a regular person on land. Among the tasks JIM suit divers tried, they found "the type of short, gross movement exemplified by sawing" to be the suit's forte.

One of them shows up in the 1981 James Bond movie, For Your Eyes Only, worn by a bad guy who attacked Bond. This is the JIM suit guy delivering a slow-motion underwater blow to 007's face. I imagine that this is about as realistic as a Michael Bay sequence in Transformers.

A JIM suit in For Your Eyes Only

Because of these limitations, Hawkes and his colleagues were eager to improve on the suit. But by that time, a company [Oceaneering] providing subsea services (mostly saturation diving) to the oil industry had purchased DHB and all the rights to its technology.

Source: here.

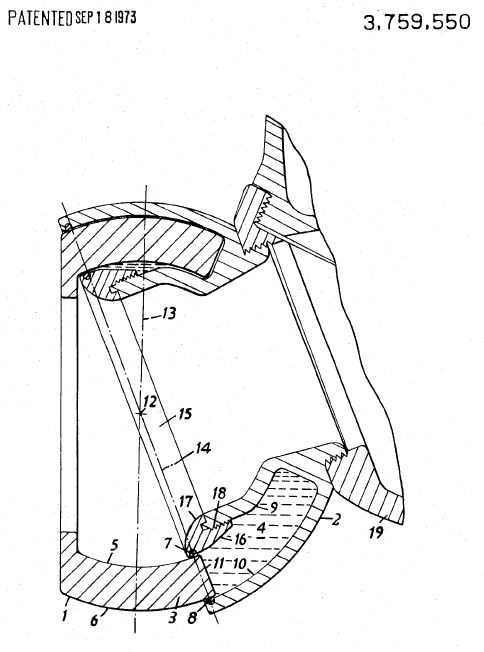

Patents used in the JIM suit variants:

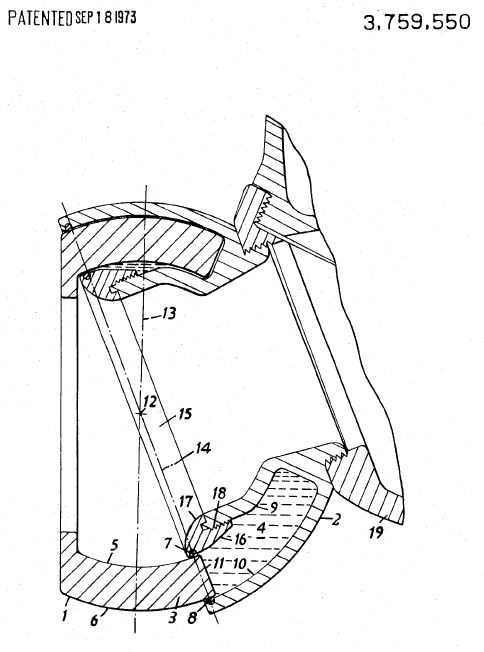

Abstract

A flexible joint for use with apparatus subjected to an internal/external pressure differential such as used in submersible diving apparatus. The joint comprises an annular male member movably housed within an annular female member. The male member has an annular piston which moves in a closed annular cylinder carrying a sealing liquid in the female member and sealing means are carried on the cylinder walls which engage and seal the walls of the annular piston.

Publication number US3759550 A

Publication type Grant

Publication date Sep 18, 1973

Filing date Aug 30, 1971

Priority date Sep 4, 1970

Also published as CA959086A1

Inventors Peress J

Original Assignee Peress J

—————————–

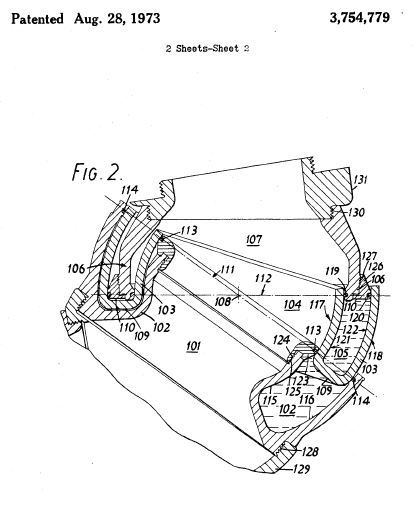

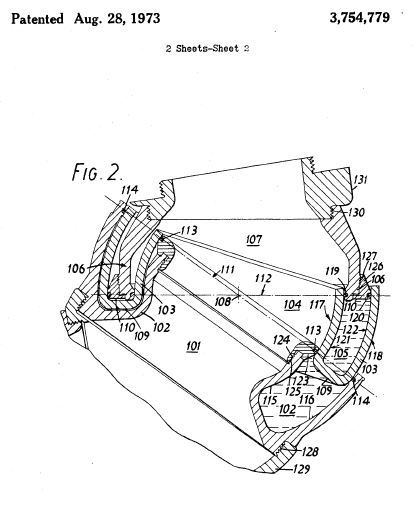

Publication number US3754779 A

Publication type Grant

Publication date Aug 28, 1973

Filing date Aug 30, 1971

Priority date Sep 4, 1970

Also published as CA941858A1

Inventors Peress J

Original Assignee Peress J

Abstract

A flexible joint for use with apparatus subjected to an internal/external pressure differential for example, submersible diving apparatus. The joint comprises an annular female member into which a relatively angularly movable annular male member can extend and which members are coupled together by an annular connecting member. The couplings between the female member and the connecting member, and between the connecting member and the male member each include an annular piston located within a part-spherical closed annular cylinder filled with fluid.

The Ken Humphrey patents. The original patents were British: GB1524033A and GB1526400A .

Published here are the US equivalents.

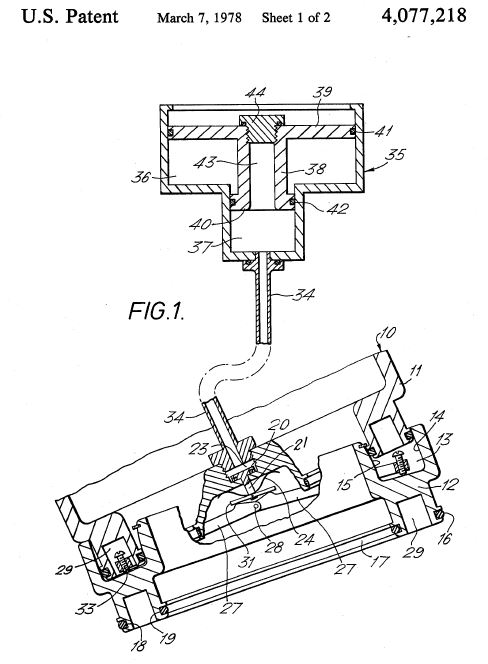

Articulated joint

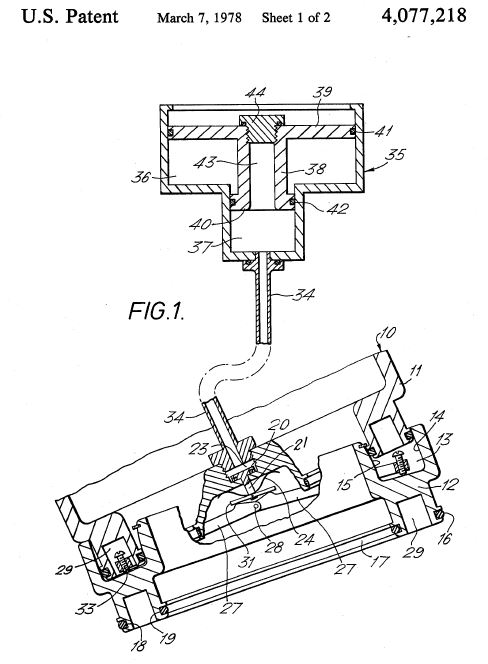

Publication number US4077218 A

Publication type Grant

Application number US 05/643,285

Publication date Mar 7, 1978

Filing date Dec 22, 1975

Priority date Dec 19, 1974

Inventors Kenneth Michael Humphrey

Original Assignee Underwater And Marine Equipment Limited

Abstract

A joint, subject to a pressure differential between inside and outside, having two tubular members flexibly joined by couplings comprising an annular piston sliding within an annular cylinder containing an incompressible fluid, a fluid reservoir connected to and at a higher pressure than the cylinder interior and valve means responsive to fluid loss from the cylinder allowing fluid flow from reservoir to cylinder. The valve may comprise two semi-circular arms pivoted at their ends to each other and to the piston or cylinder, the arms operating on opposite ends of a rocker plate attached centrally to a valve plunger. A differential piston maintains the high reservoir pressure. The valve is adjustable to operate at a predetermined value of cylinder fluid volume.

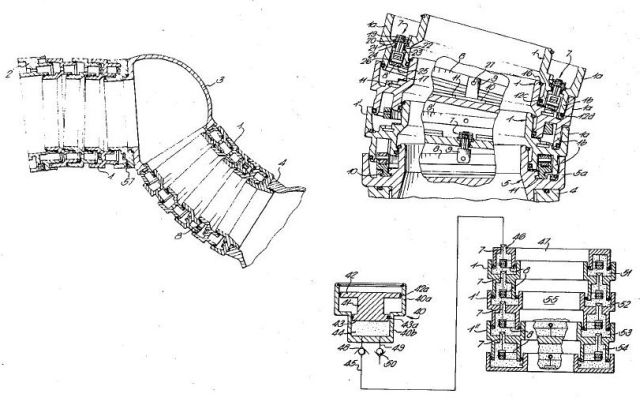

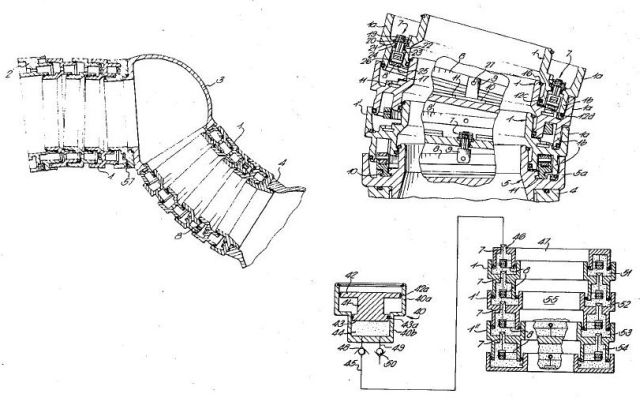

Flexible tubular joint

Publication number US4369814 A

Publication type Grant

Application number US 06/229,071

Publication date Jan 25, 1983

Filing date Jan 28, 1981

Priority date Nov 27, 1980

Fee status Lapsed

Also published as CA1153781A1

Inventors Kenneth M. Humphrey

Original Assignee Underwater And Marine Equipment Limited

Abstract

A joint which may be used in a diving suit includes a plurality of annular members each having a piston and cylinder portion which are coupled together whereby the connecting members are connected in series. The piston and cylinder portions define chambers which are filled with oil and each connecting member has valves which enable communication of the oil between adjacent connecting members as the joint is flexed. A slidably anchored gimbal mounting is provided for each valve in order to preserve the flexibility of the joint without impeding valve action and in order to prevent pullout of the adjacent piston and cylinder portions. The piston and cylinder portions each include inner and outer annular walls and the inside surfaces of the annular walls of the cylinder portions are spherically curved. The annular walls terminate in respective circular rims which are oppositely staggered. This facilitates assembly on the annular connecting members. A further arrangement ensures that the oil chambers in the serial chain on connecting members each receive an adequate supply of oil.

Some images and some further history on JIM suits see divingheritage.

I haven't credited every image use in this post. Let me know if credit for your image is required.

See other early Underwater Robots here.

The SPIDER (Self-Propelled Inspection Submarines DivER) was developed in the 1970's, in answer to the WASP. The basic design was very similar to the WASP, in that it had segmented ball and socket arm joints, a hemispherical pressure vessel for the legs and a 360° viewing dome (Wharton, 1979). One of the SPIDER's unique features were the two hydraulically operated suction pads, 'sticky feet', located in the equipment package that were intended to allow the SPIDER to attach itself to any relatively smooth surface, that is if you can find one in the barnacle encrusted sea. Additionally, rather than the 'standard' mechanical advantage manipulators found on other atmospheric diving suits, the SPIDER had hydraulically operated manipulators. An adjustable pressure relief valve permitted varying the grip pressure. Like the WASP, the SPIDER also has variable ballast control. Two SPIDERs, owned by Silvercrest Submarines, are currently operating in Hawaii in support of a scientific research program.

The SPIDER (Self-Propelled Inspection Submarines DivER) was developed in the 1970's, in answer to the WASP. The basic design was very similar to the WASP, in that it had segmented ball and socket arm joints, a hemispherical pressure vessel for the legs and a 360° viewing dome (Wharton, 1979). One of the SPIDER's unique features were the two hydraulically operated suction pads, 'sticky feet', located in the equipment package that were intended to allow the SPIDER to attach itself to any relatively smooth surface, that is if you can find one in the barnacle encrusted sea. Additionally, rather than the 'standard' mechanical advantage manipulators found on other atmospheric diving suits, the SPIDER had hydraulically operated manipulators. An adjustable pressure relief valve permitted varying the grip pressure. Like the WASP, the SPIDER also has variable ballast control. Two SPIDERs, owned by Silvercrest Submarines, are currently operating in Hawaii in support of a scientific research program.