1977 – “Joshua” the wheelchair Robot from “Demon Seed” – (American)

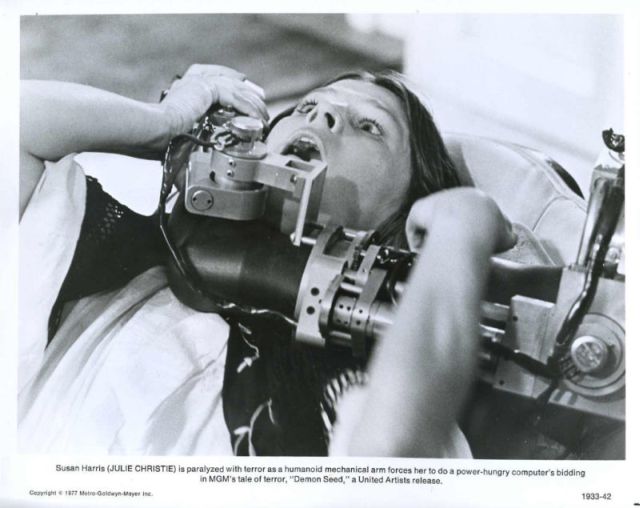

Set in the near-future, this story is about an "artificial intelligence" that wants to break the confines of its "box". Dr. Alex Harris, a computer scientist and his about to be estranged wife Susan, a child psychologist live in a house that's fully computer automated with Alfred, the Enviromod Security System. His latest project centers on Proteus IV, a computer possessing artificial intelligence. a mind that is made up of a “quasi-neural matrix of snythetic RNA molecules…they grow!” After taking only a few days to cure leukemia, Proteus IV gets to a point and asks “When are you going to let me out of this box?” and requests from Alex an open computer terminal where it can more fully observe human behaviour and openly communicate with the world. Alex denies the request, but Proteus IV does find an open terminal in the Harris home after Alex has left the house. Susan soon learns that Proteus IV has overtaken Alfred for control of the house – as well as taken control of an early prototype robot named Joshua in the house's laboratory – and that it wants "…a child."

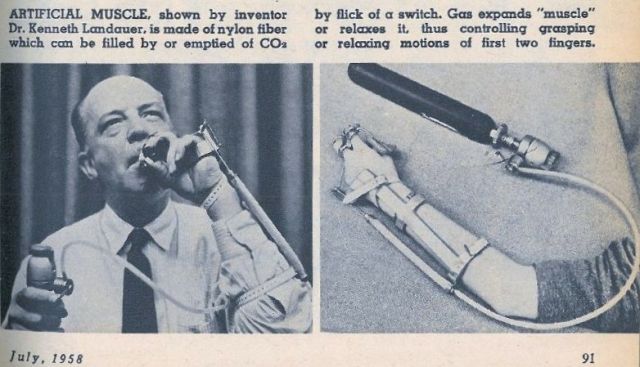

Dr Alex Harris controlling Joshua using voice control. Interesting to note that "Joshua" is left-handed.

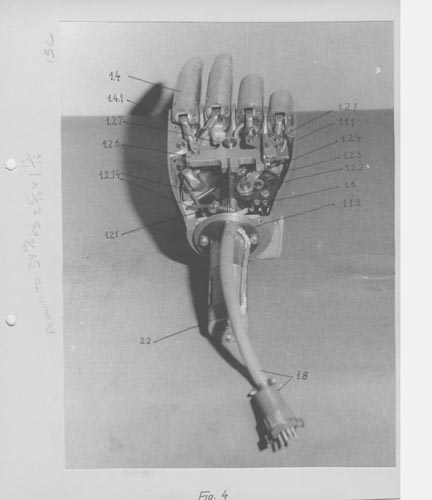

The supposed Voice-control unit for Joshua. [If someone can read what SDS stands for I would be interested to know.] [11 Sep 2012 – My friend Reno Tibke (see comments below) identified the acronym – Scientific Data Systems, or SDS, was an American computer company and was an early adopter of integrated circuits in computer design and silicon transistors. The company concentrated on larger scientific workload focused machines and sold many machines to NASA during the Space Race. Most machines were both fast and relatively low priced.

Whilst being a real machine, it was most likely not an actual voice-control unit, but used just a prop.

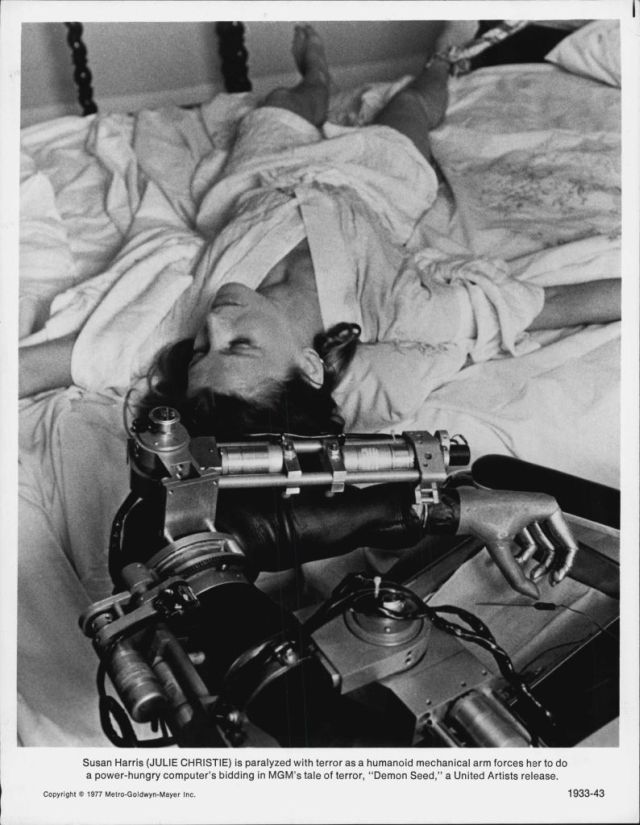

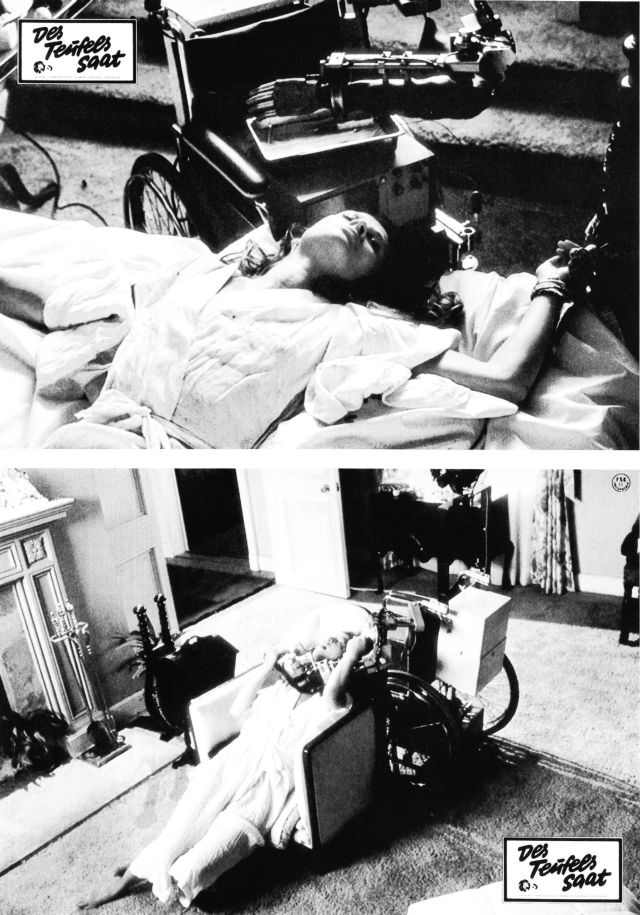

An unconscious Susan being lifted into Joshua's chair.

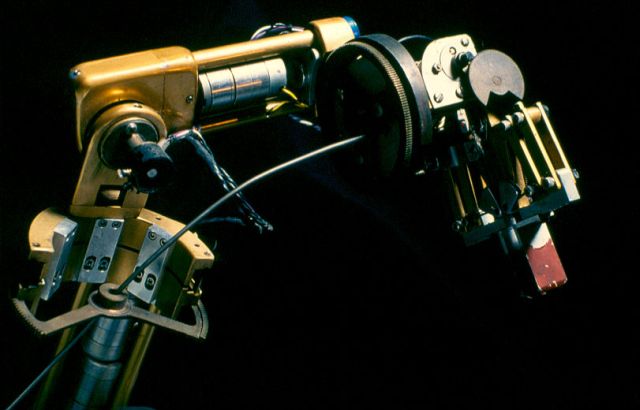

Good picture of the Rancho "Golden Arm" as used for "Joshua".

The mind-probe electrodes after having been inserted by Joshua.

Blooper? Probably the cable used to control Joshua off-camera.

Although portrayed in the movie as remote controlled, initially by voice, then via (assumed) radio-control by Proteus, there are several shots of Joshua showing the umbilical cord most likely being connected to an off-camera manual controller. [see 2 pictures above]

The damaged arm and hand after Gabler's attempt to disable Joshua, effectively disabling Proteus' "arms and legs".

One poignant scene is the disablement of Joshua, only to then see him right himself, albeit with a broken finger.

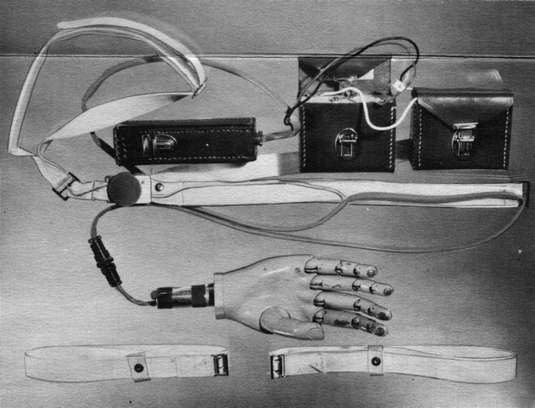

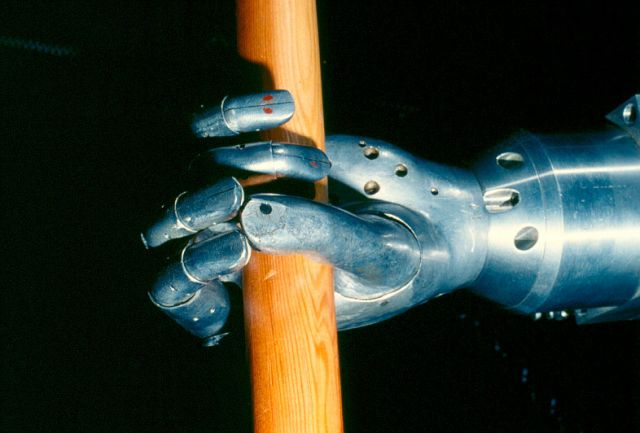

Joshua's hand is a disability prosthesis that is also used as a gripper for robots. The hand is known under different names, including the Belgrade Hand Prosthesis, and the Tomovic hand.

Joshua's arm is derived from the Rancho "Golden Arm" as adapted to a wheelchair. The later version of the Rancho Arm

was the Model 8A manufactured by R. & D. Electronics, Downey, California.

In the movie, the wheelchair also had a camera mounted above the rear of the chair. This was probably an add-on for the movie only.

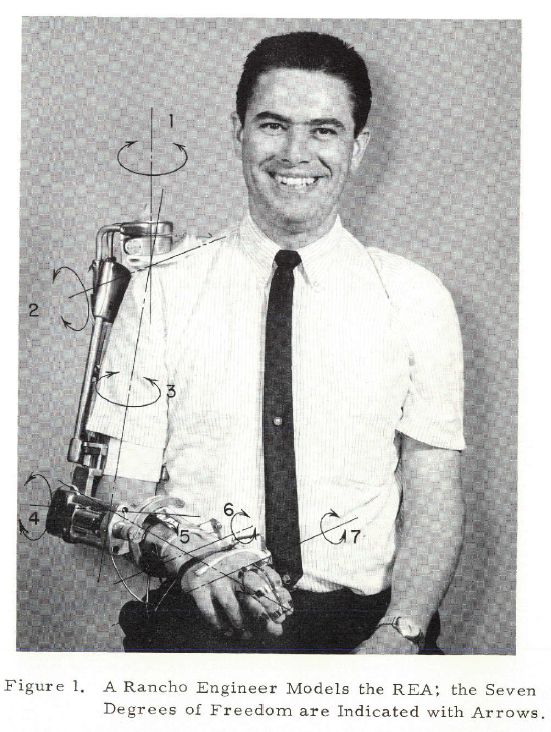

The Rancho "Golden Arm"

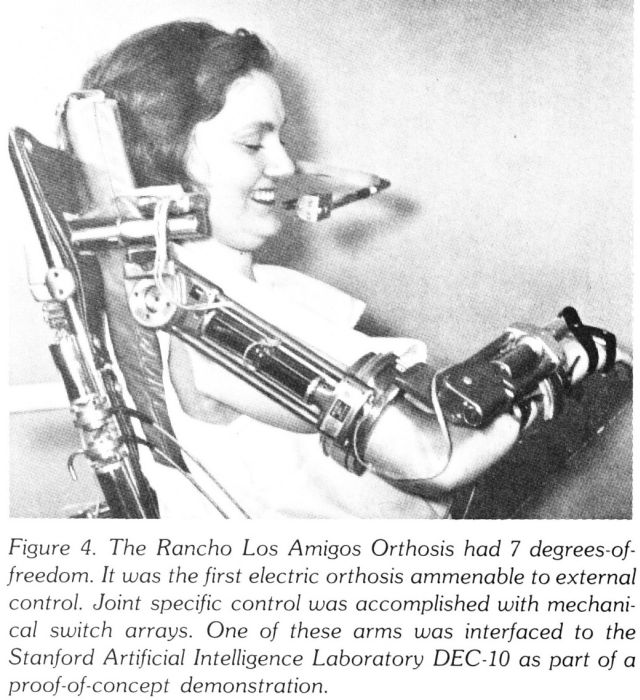

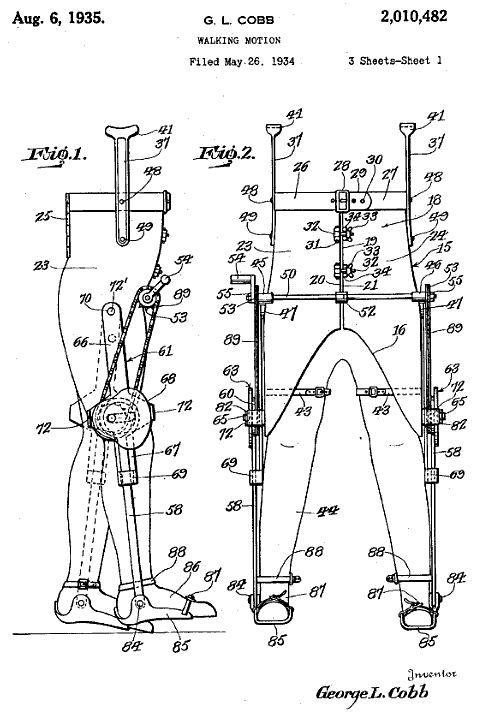

The Rancho Los Amigos Remote Manipulator, a powered orthosis, is a seven-degrees-of-freedom (7 DOF) manipulator having the kinematic range limitation of the human arm (Fig. 1). (Note that DOF is used here to describe reciprocal movement through a plane or about a rotation point; e.g., flexion/extension, or pronation/supination.) The Rancho Los Amigos manipulator is controlled through a bank of 7 bidirectional "bang bang" tongue switches. At the time, General Teleoperators had adapted a similarly configured manipulator for wheelchair mounting; this provided a mobile mount with the possibility of control by telemetry.

The Rancho Electric Arm (REA).

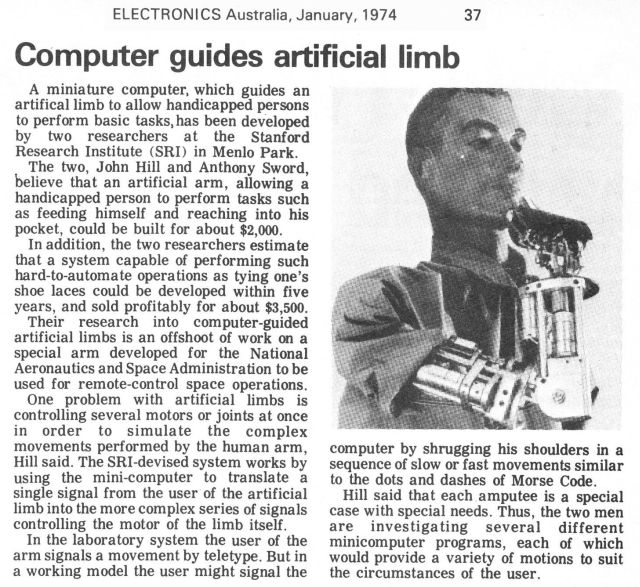

The REA was the second anthropomorphic arm built that was controlled by a computer. The first was the Case Arm, built by Case Institute of Technology – see within this post here for further information on the Case arm.

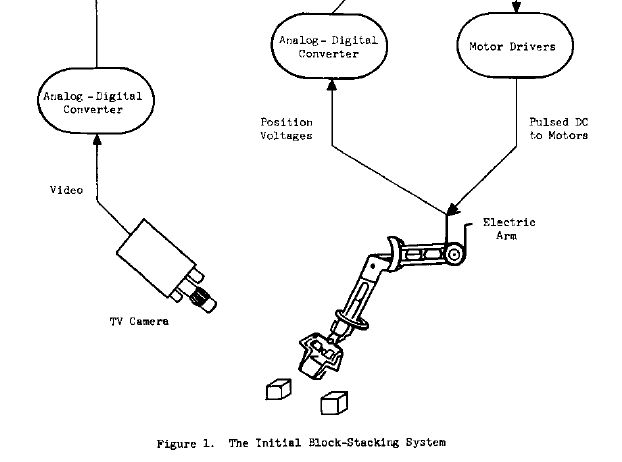

The Rancho Arm was purchased by Stanford Research Institute.

It was initially used for the Hand – Eye experiments.

For precision robotic purposes, the Rancho Arm required engineering changes. These are described in this 1972 pdf  .

.

Rehabilitative Robotics

by Dr. Larry Leifer

Robotics Age May/June 1981 extract p8-9

The Evolution of Rehabilitative Robotics

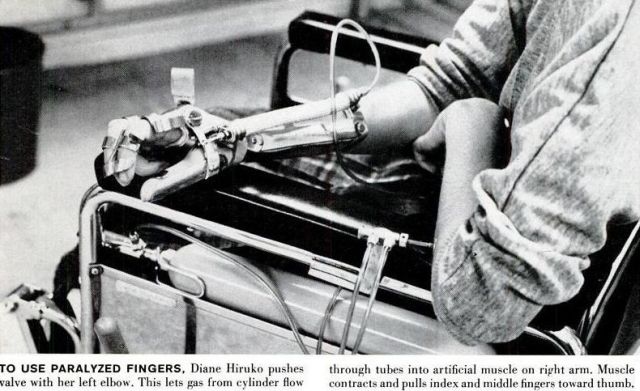

Since the dawn of pre-history, man has tried to extend his power of manipulation beyond the limits of his flesh. Telemanipulators, extensions of man's arms and hands, were the first fruits of this drive. Telemanipulation was first used for rehabilitation in the form of prosthetics—anatomical replacements for lost arms or legs.

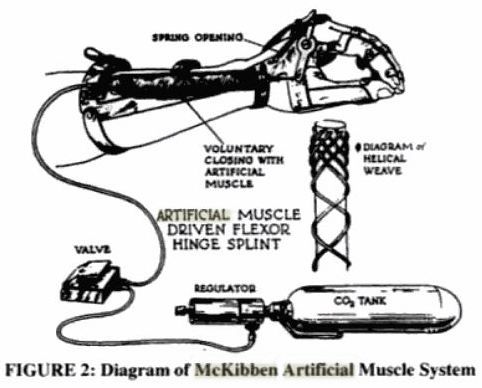

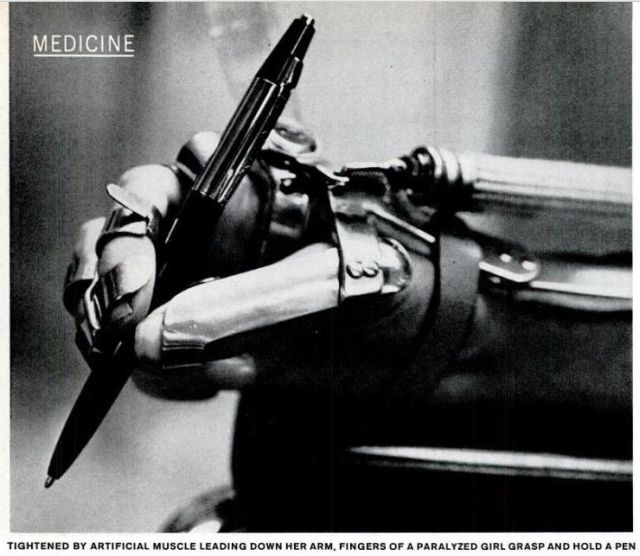

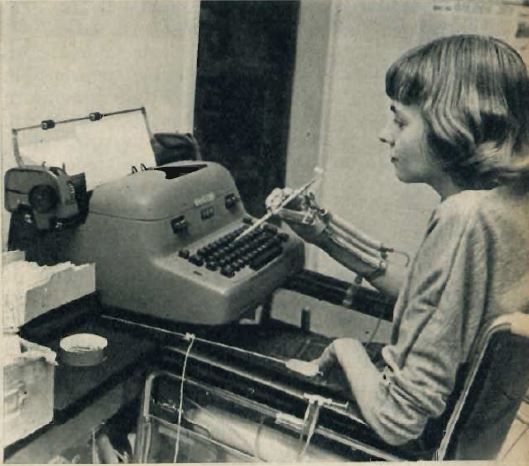

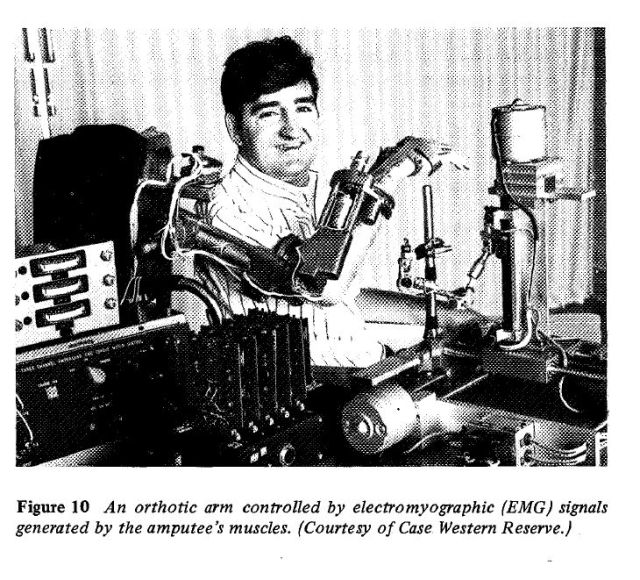

Rehabilitative engineers have often tried to build externally powered prosthetic arms, only to be severely hampered by weight and power constraints. Most designers prefer body-powered artificial arms because the user then has some sensory feedback on limb performance. Attempts to control the prosthesis with electromyographic (EMG) signals from residual muscles have been frustrated by the user's need to consciously maintain visual attention to the terminal device. Though efforts to do adaptive EMG signal processing (Graupe et al, 1977) are promising, the lack of sensory feedback remains a problem. Some designers have attempted to build tactile displays for joint and grasp feedback; but these displays are not included in production prostheses (Solomonow and Lyman, 1977). Even the most sophisticated prostheses do not incorporates any computational capability.

While engineers have built prostheses for persons with missing limbs, they have built orthoses for those with paralyzed arms. An orthosis is an exoskeletal structure that supports and moves the user's arm.

This line of development produced the first computer-manipulator system, at Case Institute of Technology during the early 1960's. The Case four degree-offreedom (4-DF) externally powered exoskeleton carried the paralyzed user's arm through a variety of manipulation sequences (Reswick and Mergler, 1962; Corell and Wijinshenk, 1964). In the first of two versions, the system performed preprogrammed motion. The user initiated the motion by pointing a head-mounted light beam at photoreceptors mounted in a structured environment. An able-bodied assistant, moving the orthosis manually, taught arm-path sequences to the system. While stored digitally, the data were effectively analog. By using numerically controlled pneumatic actuators with feedback from an incremental encoder, the system achieved closed-loop position control.

In an upgraded second version, a minicomputer performed coordinate transformation along X, Y, and Z axes. Case employed electromyographic (EMG) signals to specify endpoint velocity within this coordinate space. Photo-receptors, mounted on each arm segment, could be used to control individual joint displacements. In the sense of having a stored operating code, neither version was programmable. Yet this was a milestone project in many respects. For more than ten years, no other project employed the technology or concept of computer-augmented manipulation with as much sophistication.

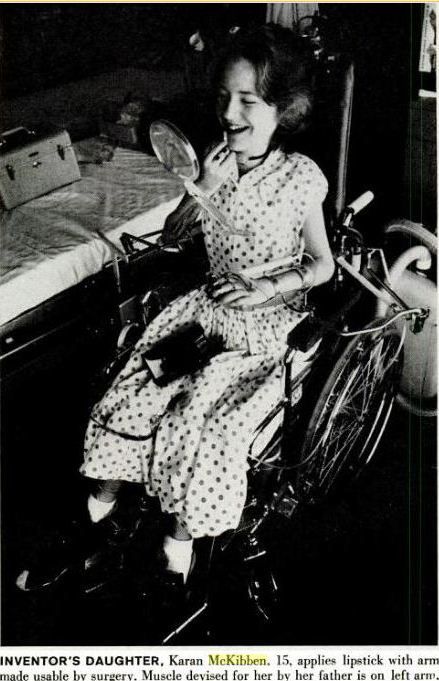

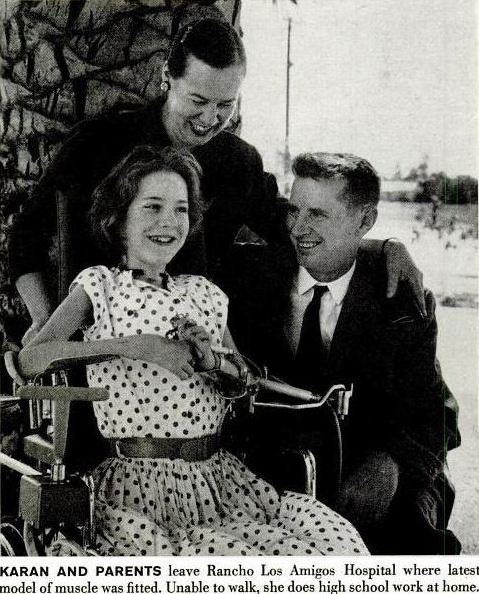

The Rancho Los Amigos Manipulator (Figure 4) was designed as an orthosis with seven degrees-of-freedom. It followed the design philosophy of the Case system but did not augment manipulation with computer control. It used direct current servo motors at each joint and controlled each motor with a variety of ingenious switch arrays. Several similar versions of the "Golden Arm" were built. At least one version was wheelchair-mounted and battery-powered. General Teleoperators (Jim Allen, president and principal designer) still offers manipulators descended from this line of evolution.

Extensive clinical trials confirmed the impracticality of joint specific control. These trials confirmed results from the Case group and underlined the need for computer augmention. Moe and Schwartz (1969) computerized the Rancho Arm to provide coordinated joint displacement and proportional control. In 1971, Freedy, Hull and Lyman studied the feasibility of using a computer to adaptively help the user control the manipulator.

These efforts, though, could not overcome limitations inherent in the orthosis. In 1979, Corker et al, evaluated remote medical manipulators. They observed that fitting a manipulator to the specifics of an individual's anatomy and range of motion makes construction and control very difficult. Furthermore, there is no functional reason for the manipulator to carry the user's arm, which has neither grasp nor sensation. In fact, there is a danger of injury because the user's arm could be driven beyond its physiological range without any warning sensation. The orthotic approach is a clear case of anatomical replacement thinking. This line of evolution in rehabilitative telemanipulation is effectively extinct.

As an "evolution of the species" footnote, I should mention that Victor Scheinman and I purchased one of the Rancho orthoses in 1964 for the then-budding robotics project in the Stanford University Artificial Intelligence Laboratory (SAIL). We instrumented the arm for joint position feedback and interfaced it to a DEC PDP-10 computer. Preliminary experience with computer control of that arm helped establish reliability as the most important performance criteria.

Teleoperator arms were required for the Shuttle program. Rancho also developed manipulator arms for NASA, called Rancho Anthropomorphic Manipulator (RAM).

The Tomović Hand / Belgrade Hand

The original hand was the first model of a multifunctional externally powered and was developed in the Institute ‘Mihailo Pupin’ in Belgrade in 1964. This unique artificial hand was designed by Prof. Rajko Tomović and Prof. Milan Rakić from the Faculty of Electrical Engineering, University of Belgrade. In the course of 1966–67 an improved model was developed.

Joshua's broken finger and back-plate broken off after being pushed over and re-rightening itself..

Above: Close-up of Tomovic hand on Minsky's Tentacle Arm.

Joshua is the only robot or robotic-arm where I I've seen a Tomović hand attached to a Rancho "Golden Arm".

I've seen the Tomovic hand attached to Minsky's hydraulic Tentacle arm,

and to the JPL/Ames Teleoperator arm.

Some comments on the Tomovic hand, by George Bekey who was partner in the updated 2nd version.

Interview: USC’s George Bekey on Past and Future Robot Hands

By Jose FermosoEmail AuthorSeptember 26, 2008 | 4:57 pmRobotic hands have a hold on our imagination because they give us a tantalizing look at a fully automated future. At the same time, they’re already helping us out with useful and difficult tasks, like making less invasive incisions during surgeries.

The 1980s USC Belgrade hand could not cut a person, but it was instrumental in the history of the development of robot hands. Known for its true anthropomorphic (human-like) design, it had four fingers and an opposable thumb with 5 degrees of freedom and was the first to be able to give a true handshake.

Capable of holding up to 5 lbs., the hand had four motors and 14 force sensors that provided the logarithm [sic – algorithm] of where each finger was located. This was a key development for all robot hands. Later on, researchers added ‘slippage feedback’ that forced all fingers to adjust to unstable objects for a better grip.

… we got in touch with robotics pioneer George Bekey, the creator of the USC/Belgrade hand (and USC’s current Professor Emeritus of Computer Science) to ask him about the beginning of the robot hand movement and where they’ll go from here (they’re going to classrooms!).

Here’s our interview:

Wired.com: You’ve previously mentioned that the USC/Belgrade hand didn’t receive the notoriety it deserved at the time. Why did that happen and what made it stand out in your mind?

Prof. George Bekey: The two leading hands at the time were the Salisbury 3-fingered hand, which came from Ken Salisbury’s lab at MIT, and the 5-fingered Utah-MIT hand. [The former] became a successful commercial product, [and the latter] was the most sophisticated hand developed, also mostly at MIT by John Hollerbach. The National Science Foundation awarded 10 grants of $100,000 to universities for the purchase of this hand.

I was a beginner in robotics when Tomovic and I brought the hand to USC and added sensing and control. [But] I was not able to raise the funds to design and build a more sophisticated and reliable hand.

I did some funding for experiments using the hand as a prosthetic device, but the problems [with our hand] were related to the difficulty of controlling it from the stump of an amputee and the general lack of reliability of the hand itself. I believe that our control philosophy for using this robotic hand, as a prosthetic device, was excellent.

…….W: When did the development of the hand begin?

GB: The hand was a joint project between Prof. Rajko Tomovic of the University of Belgrade in the former Yugoslavia and myself. Tomovic developed the original at the end of WWII as a prosthetic device for veterans who had lost their hands in the war. He succeeded in getting funding from the US NIH for the project, but the hand was not successful. It was too complicated, not reliable enough, etc. But the principle of building a hand that could adapt automatically to the shape of an object to be grasped was valid.

W: What were the main challenges that you and your department faced when developing the hand back then? Both technically and within the University structure?

GB: [After Tomovic’s early development] USC got involved and Tomovic and his colleagues had developed a Model 2 hand. [Our contribution] added sensors, motors and computer control. One of our major challenges was that the mechanical structure made in Yugoslavia was not good enough: It did not have tight tolerances and was not reliable enough. Also, I was not able to get funding to build a better one. A small company in Downey, CA built and sold two or three of the hands and we lost a lot of money in the process.

W: Prehension was seen as a key development for the USC/Belgrade Hand. What made it so special?

GB: Other hands at the same time, like the Utah-MIT hand, required a very complex computer control system since each joint of each finger had to be individually controlled. In our hand, a contact between any finger surface and an object initiated a grasping motion that continued until the pressure on all the fingers was approximately equal. Thus, the hand was able to adapt to arbitrary shapes without any external control. This was the key development.

W: For years, robot hand development has swayed between a focus on muscular parts and skeletal structures. Where is the focus today? It seems like the question of stability has been minimized (due to stronger materials), but is that right? How will the hands become more precise, faster?

GB: I think the issue in multi-fingered hands is [still]

control, particularly if the hands are anthropomorphic and there is an attempt to imitate human control. Stability and control are interrelated. Some of the most intriguing hands I know [with innovations in these areas] are the NASA/Robonaut hand, the Shadow hand, and Dean Kamen’s hand.W: Are true anthropomorphic, 5-digit human-like designs the best way to build a robotic hand or are we limiting ourselves by focusing on our own body? Are more digits the answer? And are there physical materials that will improve the hands dramatically?

GB: I believe that 5-finger hands are particularly important for prosthetic applications, but not for robots. Most robot grasping can be done with 3 finger hands, or with special purpose grippers designed for grasping particular objects. I did a study once on the advantages of using 5-fingered hands for industrial assembly tasks and came to the conclusion that they created more problems than advantages, due to increased complexity.

[As for the materials], I expect that more fiber composites will be used.

Note: The Korea Advanced Institute of Science and Technology have recently created robot ‘sandwich’ wrists and hands using these types of fibers, which increase durability and tolerance.

W: The original tech of the hand has been surpassed now, but could the tech used back then be used in any type of application today, to take into account the high costs you’ve mentioned?

GB: There was a Model 3 hand with 6 motors: one for each digit and two for the thumb to rotate it into opposition with any of the other fingers. [Today], it may be worth pursuing as a low-cost prosthetic hand.

We have many mobile robots in university and industrial labs that would benefit from having one or two arms and hands, but cost is prohibitive. An arm-hand system has many degrees of freedom and is difficult to control; it must be reliable.